Unveiling the Excellence of a China Plastic Injection Molding Manufacturer

In today’s competitive market, the need for top-notch manufacturing solutions is paramount. Among the various manufacturing techniques, plastic injection molding stands out as a remarkable process that allows for high efficiency and precision. As a prominent China plastic injection molding manufacturer, DeepMould harnesses advanced technology and expertise to deliver superior products tailored to meet diverse industry needs.

Understanding Plastic Injection Molding

Plastic injection molding is a manufacturing process that involves injecting molten plastic into a mold. Once cooled, the mold is removed to reveal a finished part. This technique is favored for its ability to produce intricate designs with tight tolerances, making it essential in various sectors, including automotive, medical, and consumer goods.

The Process of Plastic Injection Molding

The injection molding process generally consists of several key steps:

- Material Selection: Choosing the right type of plastic resin is crucial, as it affects the final product's durability, flexibility, and overall performance.

- Designing the Mold: Molds are custom-designed using CAD software to ensure accuracy and meet specific design requirements.

- Injection: The plastic resin is heated until molten, then injected into the mold under high pressure.

- Cooling: Once the plastic fills the mold, it is allowed to cool and solidify.

- Demolding: After cooling, the mold is opened, and the finished part is ejected.

- Finishing: Additional processes such as trimming, painting, or assembling may be applied as needed.

Why Choose DeepMould as Your China Plastic Injection Molding Manufacturer?

Choosing the right manufacturer can significantly impact your project’s success. Here’s why DeepMould stands out among Chinese plastic injection molding manufacturers:

1. Experience and Expertise

With over a decade of experience in the industry, DeepMould has honed its skills and knowledge in advanced injection molding techniques. Our team of experienced engineers and technicians are dedicated to producing high-quality molds and components that meet international standards.

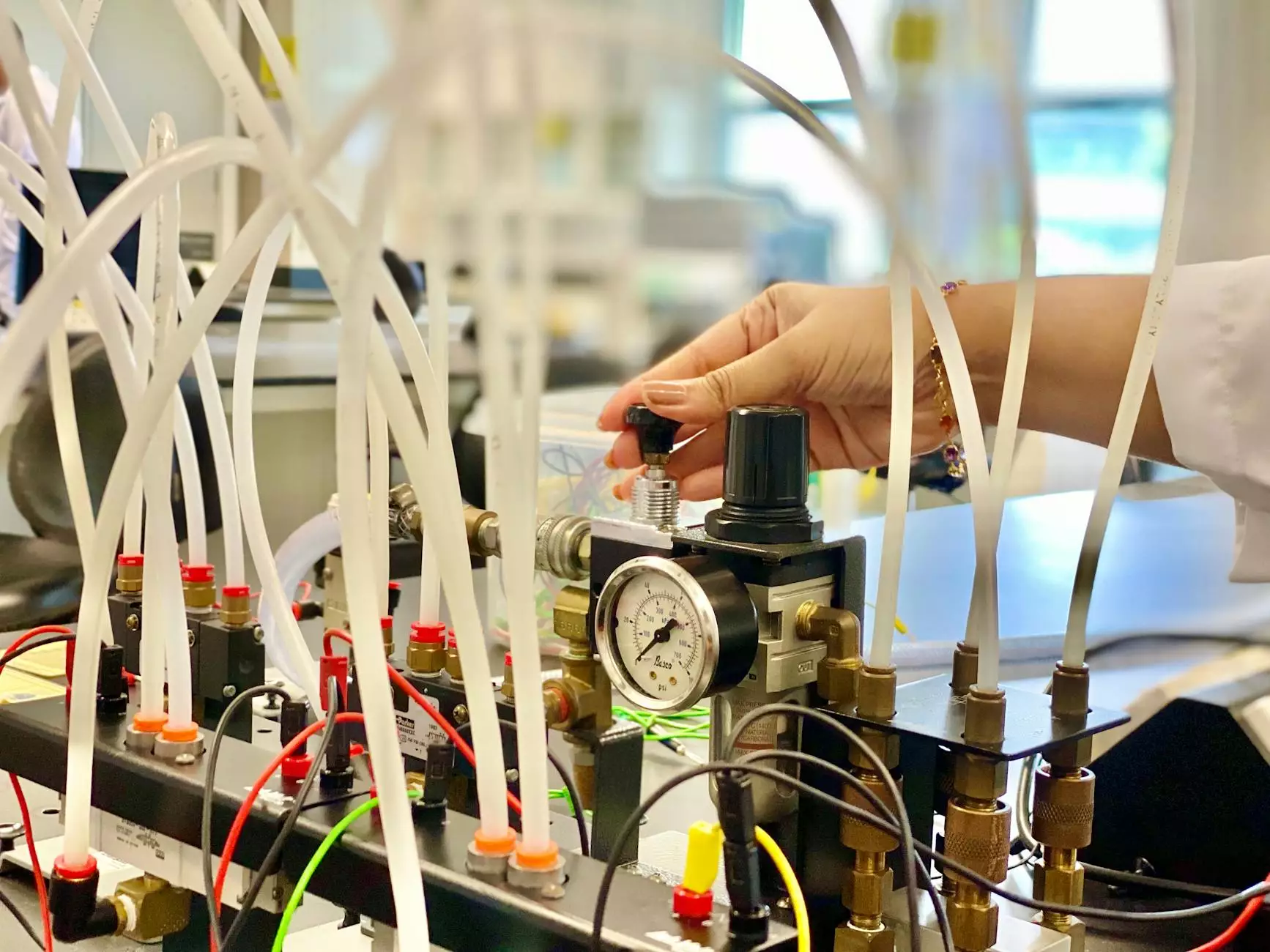

2. Advanced Technology

At DeepMould, we utilize state-of-the-art machinery and the latest software for designing and manufacturing molds. Our facility is equipped with CNC machines, 3D printers, and advanced injection molding machines that enhance efficiency and allow us to achieve intricate designs with precision.

3. Quality Assurance

Quality is at the heart of our operations. As a leading China plastic injection molding manufacturer, we adhere to strict quality control measures throughout the production process. Our dedicated quality assurance team conducts rigorous testing to ensure every component meets the required specifications and standards.

4. Customization Options

We understand that each project comes with unique requirements. That’s why we offer customizable solutions tailored to your specific needs. From material selection to mold design, our team collaborates with you to ensure the final product aligns with your vision.

5. Cost-Effective Solutions

DeepMould provides competitive pricing without compromising on quality. Our efficient manufacturing processes and bulk production capabilities help reduce costs, making us a cost-effective choice for businesses of all sizes.

Industry Applications of Plastic Injection Molding

The versatility of plastic injection molding makes it suitable for a wide range of applications. Here are some key industries that benefit from this innovative manufacturing process:

- Automotive: Production of parts such as dashboards, bumpers, and interior components.

- Medical: Creation of medical devices, surgical tools, and packaging.

- Consumer Goods: Manufacturing everyday items like kitchenware, toys, and personal care products.

- Electronics: Development of enclosures, housings, and components for electronic devices.

- Industrial: Making parts for machinery, equipment, and tools.

The Future of Plastic Injection Molding

As technology continually evolves, the future of plastic injection molding seems promising. Innovations such as 3D printing, automation, and enhanced material properties are set to revolutionize the industry. At DeepMould, we are committed to staying at the forefront of these advancements, ensuring we continue to meet the needs of our clients effectively.

Sustainable Practices in Injection Molding

Environmental responsibility is a crucial concern for the manufacturing industry, and DeepMould is no exception. We actively seek ways to minimize waste and reduce our carbon footprint through sustainable practices, such as:

- Using recyclable and biodegradable materials.

- Implementing energy-efficient machinery.

- Optimizing production processes to reduce scrap and waste.

Conclusion: Partner with DeepMould Today

In the ever-evolving business landscape, having a reliable and experienced partner in manufacturing is invaluable. As a leading China plastic injection molding manufacturer, DeepMould is dedicated to turning your ideas into tangible, high-quality products. With our advanced technology, commitment to quality, and customer-centric approach, we are poised to support your business's growth and innovation.

Don’t hesitate to contact us today for a consultation, and discover how we can help bring your projects to life with precision and efficiency.