Understanding China Crankshaft Manufacturers: A Comprehensive Insight

In the ever-evolving landscape of the diesel engine parts industry, the significance of China crankshaft manufacturers cannot be overstated. These manufacturers play a critical role in supplying high-quality crankshafts that are essential for the performance and efficiency of diesel engines. In this article, we will explore the dynamics of the crankshaft manufacturing sector in China, its implications for the global market, and why choosing the right manufacturer is paramount for businesses seeking spare parts.

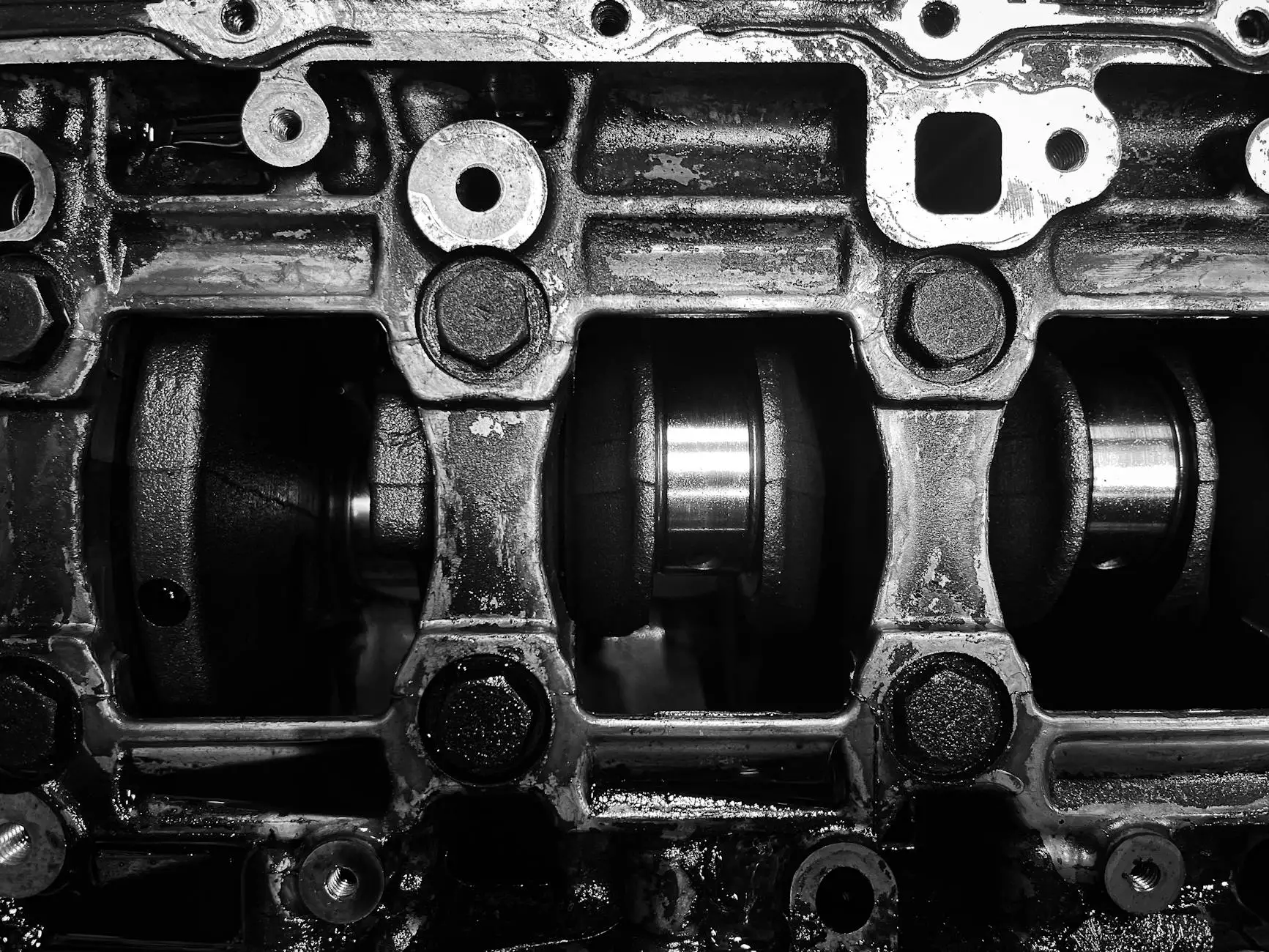

The Importance of Crankshafts in Diesel Engines

A crankshaft is a fundamental component in any internal combustion engine. It's the part that converts the linear motion of the pistons into rotational motion, which ultimately drives the vehicle. In diesel engines, the crankshaft must endure extreme stresses and loads. Thus, understanding the role that China crankshaft manufacturers play in producing these vital components is essential.

Key Functions of the Crankshaft

- Power Generation: It converts linear motion into rotational energy.

- Support: Provides structural support for other engine components.

- Balance: Helps maintain engine balance and reduces vibrations.

- Timing: Plays a crucial role in maintaining the timing of the engine’s operations.

The Landscape of Crankshaft Manufacturing in China

China has emerged as a leading hub for manufacturing various engine components, including crankshafts. The country's rapid industrial growth, combined with its advanced manufacturing technologies, positions it as a crucial supplier of crankshafts for the global market.

Factors Contributing to China's Crankshaft Manufacturing Dominance

- Advanced Technology: Chinese manufacturers invest heavily in technology to produce precision-engineered parts.

- Skilled Workforce: Access to a large and skilled labor force enhances manufacturing efficiency.

- Cost-Effectiveness: Competitive labor costs make Chinese crankshaft manufacturers more attractive to global buyers.

- Established Supply Chains: Proximity to raw materials and components promotes a robust manufacturing ecosystem.

Categorizing the Market: Types of Crankshafts

Within the realm of China crankshaft manufacturers, there are several types of crankshafts designed for different engine types. Understanding these variations is crucial when sourcing parts.

- Forged Crankshafts: Known for their durability and strength, fabricated from a single piece of metal.

- Cast Crankshafts: Economically viable and used in various engine models, offering a balance of strength and weight.

- Billet Crankshafts: Precision-engineered from solid metal, these crankshafts are used in high-performance applications.

The Manufacturing Process of Crankshafts

Understanding how crankshafts are produced provides insights into the quality and reliability of the products from China crankshaft manufacturers.

1. Material Selection

The first step in crankshaft manufacturing involves selecting the right material, usually steel or iron, that can withstand high stress and wear.

2. Forging and Casting

Depending on the type of crankshaft, manufacturers may use forging for strength or casting for cost-effectiveness. This process shapes the raw material into the desired form.

3. Machining

After forging or casting, the crankshaft undergoes precision machining where dimensions are finely tuned. This step ensures that each crankshaft meets strict specifications.

4. Surface Treatment

A critical step that involves applying coatings to enhance wear resistance and corrosion protection, thereby prolonging the life of the crankshaft.

5. Quality Control

Stringent quality control measures are implemented at various stages of manufacturing to ensure the final product meets international standards.

Quality Assurance Practices Among China Crankshaft Manufacturers

For buyers, the quality of crankshafts is a prime concern. Here’s how China crankshaft manufacturers ensure their products meet high standards.

- ISO Certification: Many manufacturers are ISO certified, ensuring adherence to global quality management standards.

- Material Testing: Rigorous testing of raw materials to verify strength and durability.

- Dimensional Verification: Advanced equipment is used for measuring and checking precise dimensions of the crankshafts.

- Performance Testing: Evaluation under simulated operational conditions to ensure reliability.

Challenges Faced by China Crankshaft Manufacturers

While the outlook for China crankshaft manufacturers is promising, several challenges must be addressed to maintain their competitive edge.

1. Environmental Regulations

Increasingly stringent environmental regulations require manufacturers to adopt sustainable practices, which can lead to higher operational costs.

2. Trade Tariffs and Policies

The fluctuating trade policies and tariffs can affect pricing and accessibility of Chinese manufactured parts in international markets.

3. Market Competition

As other countries also ramp up their manufacturing capabilities, competition is becoming stiff, requiring constant innovation from Chinese manufacturers.

Selecting the Right Manufacturer

When sourcing crankshafts, it's essential for businesses to consider several factors when choosing a manufacturer in China:

1. Reputation and Experience

Look for manufacturers with a proven track record in the industry, as this often correlates with reliability and quality.

2. Manufacturing Capabilities

Assess their technological capabilities, production capacity, and whether they produce the specific type of crankshaft required.

3. Customer Service

Evaluate their customer service approach, including responsiveness and support. A reputable manufacturer should provide adequate assistance before and after the purchase.

4. Pricing Structure

While price shouldn't be the only deciding factor, it is essential to compare pricing structures among various manufacturers to find a balance between cost and quality.

Conclusion: The Future of China Crankshaft Manufacturers

As the demand for advanced diesel engine parts continues to grow, China crankshaft manufacturers are poised to play an even larger role in the global market. With their commitment to quality, innovation, and technological advancement, they are set to meet the challenges of the future. Businesses looking for reliable crankshafts and other spare parts should consider the vast potential that these manufacturers offer. By making informed choices and choosing the right partners in this sector, firms can enhance their operations and thrive in the competitive market landscape.

Explore Our Offerings

If you’re seeking top-quality crankshafts and other diesel engine parts, look no further than client-diesel.com. We connect you with reputable suppliers and manufacturers from China, ensuring that you receive only the best components for your operational needs.