Revolutionizing Refrigeration: The Future of Cold Chain Solutions

In today's global market, businesses rely heavily on efficient logistics and supply chain management. One of the critical components of this system is the cold chain, which ensures that temperature-sensitive products are stored, transported, and preserved under ideal conditions. Companies like First Cold Chain are at the forefront of providing advanced refrigeration equipment and solutions that streamline cold chain operations.

The Importance of Cold Chain Logistics

The cold chain refers to a temperature-controlled supply chain used for a variety of products, including pharmaceuticals, perishable foods, and other sensitive items. The significance of an intact cold chain cannot be overstated:

- Quality Preservation: Maintaining the appropriate temperature ensures that products retain their quality and efficacy from the point of origin to the final consumer.

- Safety Compliance: For pharmaceuticals and food products, adhering to strict temperature controls is crucial for safety and compliance with regulatory standards.

- Waste Reduction: Improved temperature control helps minimize spoilage and waste, which is economically beneficial.

- Consumer Trust: Businesses utilizing a reliable cold chain enhance their reputation and trust with consumers, ensuring repeated sales and customer loyalty.

Key Components of Effective Refrigeration Equipment

Effective cold chain management depends on the use of reliable refrigeration equipment. Here are some critical components that businesses should consider:

1. Refrigerated Transport Vehicles

Refrigerated trucks and vans play an essential role in transporting temperature-sensitive goods. These vehicles must be equipped with state-of-the-art cooling systems that are capable of maintaining consistent temperatures. Innovations in refrigeration technology allow for even better energy efficiency and temperature monitoring.

2. Cold Storage Facilities

Modern cold storage facilities are the backbone of cold chain logistics. They need to be designed with optimal insulation and temperature control systems to ensure the integrity of stored products. Companies like First Cold Chain provide customized solutions that cater to the specific needs of different industries.

3. Temperature Monitoring Systems

Integrating advanced temperature monitoring technologies, such as IoT sensors, can drastically improve oversight. These systems provide real-time data that helps businesses ensure compliance with temperature regulations and quickly respond to any anomalies that may arise.

4. Packaging Solutions

Proper packaging is vital in maintaining the desired temperature throughout the supply chain. Implementing insulated containers or temperature-controlled packaging can significantly reduce the risk of temperature deviations during transit.

Innovation in Refrigeration Equipment

The refrigeration industry is constantly evolving, and businesses must stay informed about the latest innovations to remain competitive. Here are some of the notable trends:

1. Energy-Efficient Solutions

As sustainability becomes a growing concern, the demand for energy-efficient refrigeration solutions continues to rise. Technologies such as variable speed compressors and advanced refrigeration liquids contribute to lower energy consumption and reduced operational costs.

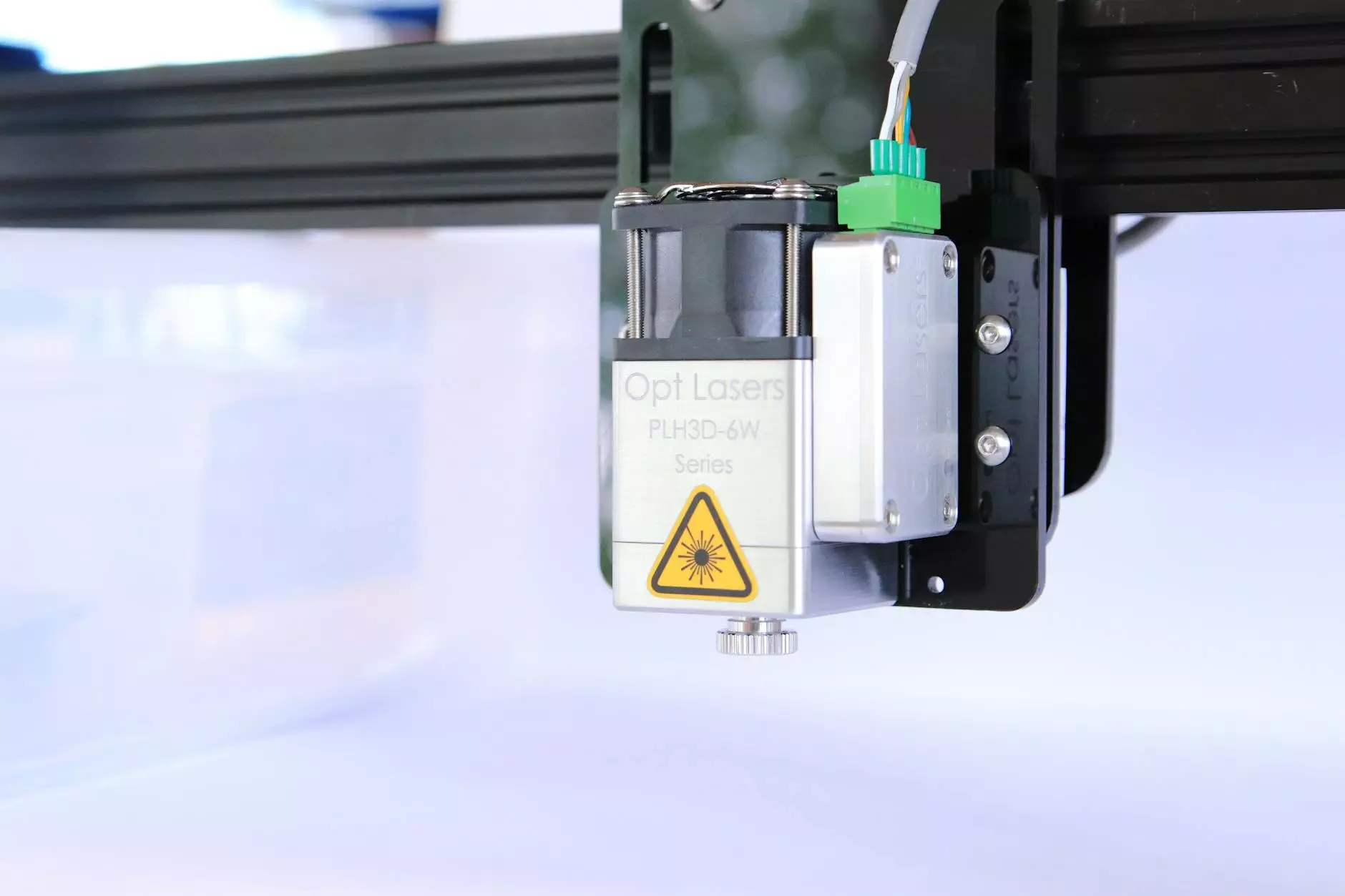

2. Smart Technology Integration

Smart technologies allow for enhanced visibility and tracking of shipments. Utilizing connected devices within refrigeration equipment enables businesses to receive alerts regarding temperature fluctuations, ensuring that corrective measures are promptly taken.

3. Automation in Cold Chain Operations

Automation can significantly improve the efficiency of cold chain processes. Automated loading and unloading systems, AI-driven route optimization for transportation, and robotic warehousing solutions are becoming more commonplace in the industry.

Challenges in Cold Chain Logistics

While the cold chain industry is advancing, several challenges remain. It's crucial for businesses to recognize and adapt to these obstacles to optimize their operations:

1. Regulatory Compliance

Compliance with various regulatory standards, including those set by the FDA and other governing bodies, can be complex and demanding. Companies must ensure all their equipment and practices align with these regulations.

2. Cost Management

The upfront investment in high-quality refrigeration equipment can be significant. Businesses need to manage these costs effectively while navigating returns on investment.

3. Skill Shortages

A skilled workforce is required to handle modern refrigeration systems and technologies. The industry faces a talent gap, making it critical for companies to invest in training and development.

Choosing the Right Partner for Refrigeration Equipment

Selecting the right partner for your refrigeration needs is essential. Here are some factors to consider when evaluating potential suppliers:

- Experience and Reputation: Look for partners with a proven track record of reliability and quality.

- Customization Capabilities: A good provider will offer tailored solutions that meet your specific requirements.

- Customer Support: Ensure they have robust customer service to assist you after the purchase.

- Innovation: Choose partners committed to staying at the forefront of technology advancements in the refrigeration industry.

Conclusion: The Future is Bright for Cold Chain Services

The cold chain sector plays a pivotal role in global commerce, maintaining the quality and safety of products that we rely on every day. Companies such as First Cold Chain exemplify how innovation in refrigeration equipment can lead to more efficient and effective operations. With the integration of advanced technologies and a focus on sustainability, the future of cold chain logistics looks promising. As businesses continue to adapt and innovate, the importance of reliable cold chain solutions will only increase.

https://www.first-coldchain.com/