Laser Heat Treating of Automotive Stamping Dies

Sheet Metal

Why Choose Laser Heat Treating for Automotive Stamping Dies?

In the automotive industry, precision and durability are of utmost importance. To ensure the longevity and performance of automotive stamping dies, it is crucial to employ an advanced heat treating technique like laser heat treating.

The Benefits of Laser Heat Treating

Laser heat treating offers numerous benefits that make it an ideal choice for automotive stamping dies:

- Enhanced Hardness: Laser heat treating improves the hardness of the die material, resulting in superior resistance against wear and deformation. This extends the lifespan of the dies, reducing the need for frequent replacements.

- Precision: With laser heat treating, precise control over the heat distribution allows for localized hardening of critical areas on the stamping dies. This precision ensures dimensional accuracy and improves overall part quality.

- Minimal Distortion: Compared to traditional heat treating methods, laser heat treating minimizes distortion and warping of the stamping dies. This ensures that the dies maintain their original shape and dimensions, leading to consistent and reliable performance.

- Improved Surface Finish: Laser heat treating results in a smoother surface finish on the stamping dies, reducing the need for additional finishing or polishing processes. This not only saves time but also enhances the aesthetic appeal of the finished automotive parts.

- Shorter Lead Times: With laser heat treating, the process can be completed rapidly and with high efficiency. This helps reduce overall production time, allowing businesses in the automotive industry to meet tight deadlines and increase their productivity.

The Laser Heat Treating Process

The laser heat treating process involves several key steps:

- Cleaning and Preparing the Dies: Before laser heat treating, the automotive stamping dies are thoroughly cleaned and prepared to remove any contaminants that could affect the treatment process.

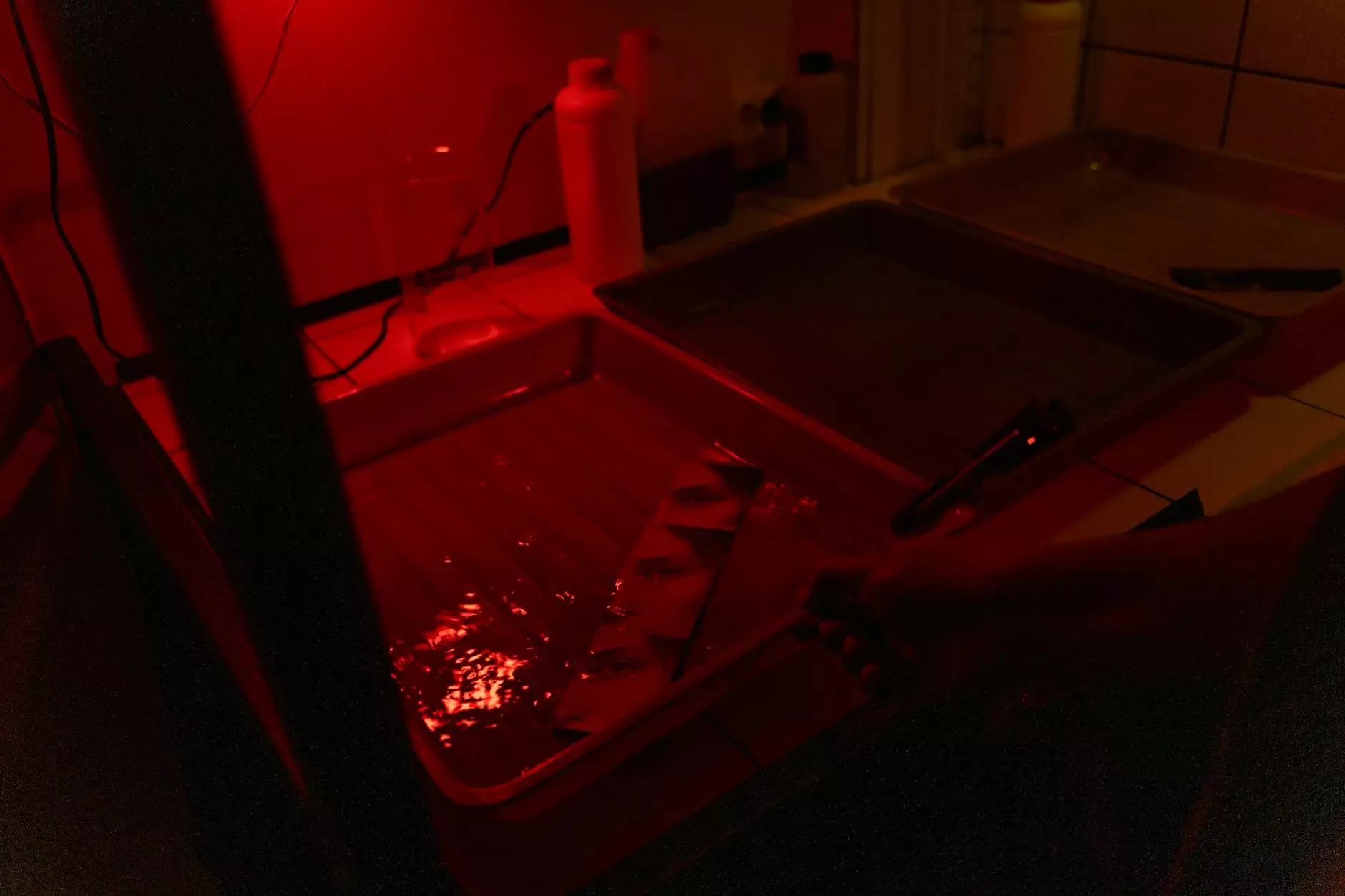

- Applying Laser Energy: A high-powered laser is used to apply controlled heat energy to the surface of the dies. The laser's heat source is precisely targeted to achieve the desired hardness and heat distribution.

- Quenching: After the laser energy is applied, the stamping dies are rapidly quenched to cool them down. This step helps lock in the desired hardness and prevents excessive heat from affecting the material's properties.

- Post-Treatment Inspection: Once the laser heat treating process is complete, the automotive stamping dies undergo thorough inspection to ensure they meet the required hardness and dimensional specifications.

Partner with Powder Keg for Laser Heat Treating

As a leader in the business and consumer services industry, Powder Keg specializes in providing high-end laser heat treating services for automotive stamping dies. We understand the unique needs of the automotive industry and strive to deliver precision, quality, and unparalleled durability to our clients.

Our experienced team of experts utilizes state-of-the-art laser heat treating equipment and follows strict quality control measures to ensure superior results. We are committed to delivering outstanding customer satisfaction and helping businesses in the automotive sector optimize their die performance.

When you choose Powder Keg for laser heat treating, you can expect:

- Unmatched Expertise: Our team comprises highly skilled professionals with extensive knowledge and experience in laser heat treating for automotive stamping dies.

- Advanced Equipment: We invest in cutting-edge laser heat treating technology to ensure precise, efficient, and consistent results for our clients.

- Quality Assurance: Every step of the laser heat treating process is meticulously monitored and inspected to maintain the highest standards of quality and accuracy.

- Custom Solutions: We understand that each automotive stamping die has unique requirements. Therefore, we work closely with our clients to develop customized heat treating solutions tailored to their specific needs.

- Reliability and Timeliness: At Powder Keg, we prioritize customer satisfaction and adhere to strict timelines, ensuring prompt delivery of our laser heat treating services.

- Competitive Pricing: We offer competitive pricing options without compromising on the quality and effectiveness of our laser heat treating solutions.

Contact Powder Keg for Laser Heat Treating Services

If you're looking to optimize the performance and durability of your automotive stamping dies, Powder Keg is here to help. Our cutting-edge laser heat treating services are designed to elevate your die quality, enhance efficiency, and increase overall productivity.

Reach out to Powder Keg today to discuss your laser heat treating needs. Our friendly team will be happy to provide detailed information, answer any questions, and offer expert guidance tailored to your specific requirements.