Tungsten Carbide Laser Hard Facing

Introduction

Welcome to Powder Keg, your premier provider of high-end laser coating services in the Business and Consumer Services category. In this article, we will delve into the world of Tungsten Carbide Laser Hard Facing, exploring its benefits and applications for businesses like yours.

What is Tungsten Carbide Laser Hard Facing?

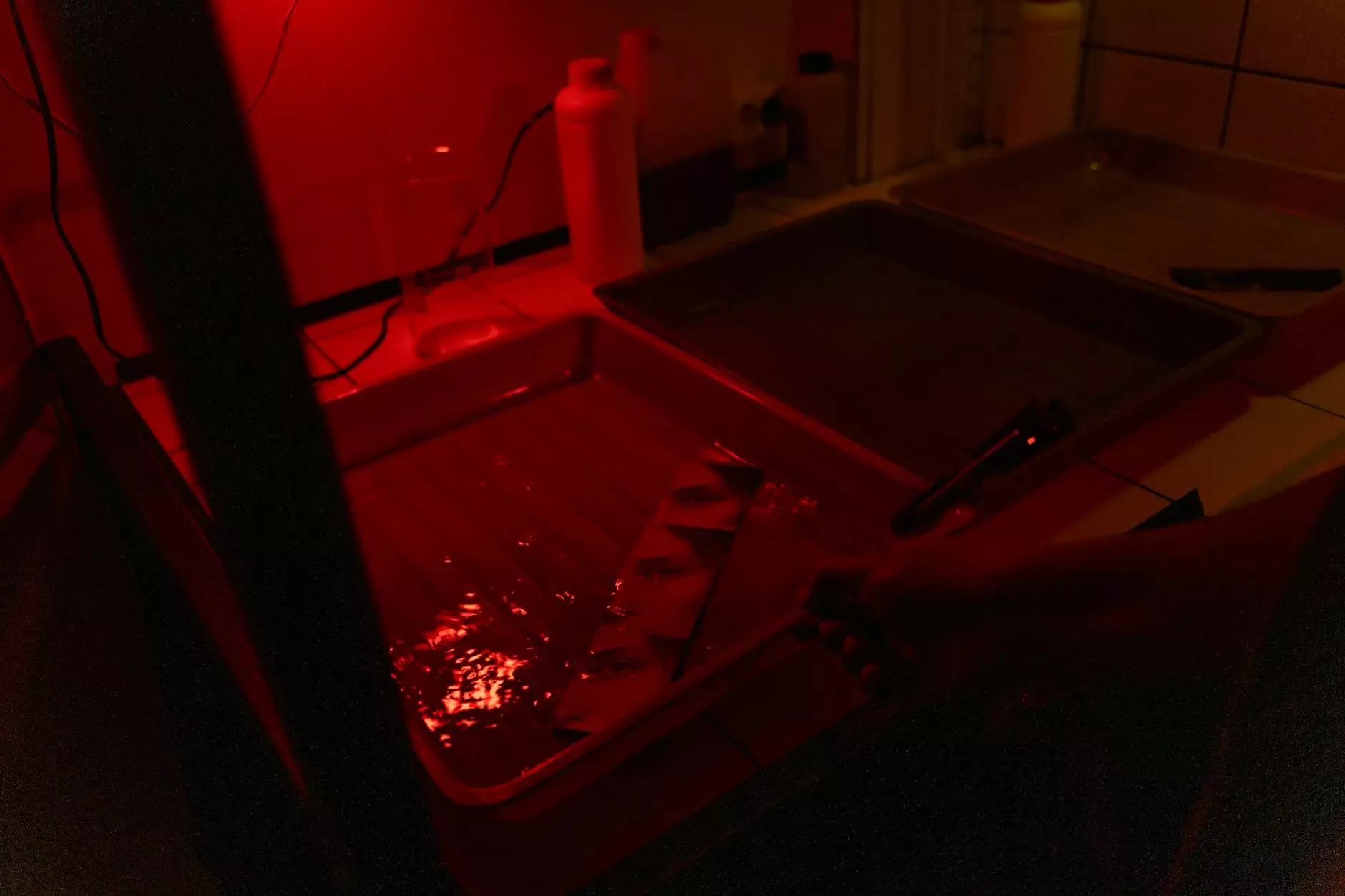

Tungsten Carbide Laser Hard Facing is a cutting-edge technology that involves the application of a thin layer of Tungsten Carbide onto a substrate using laser cladding. This process enhances the hardness, wear resistance, and overall performance of the coated material, making it suitable for a wide range of industrial applications.

The Benefits of Tungsten Carbide Laser Hard Facing

1. Enhanced Durability

The primary advantage of Tungsten Carbide Laser Hard Facing is its ability to significantly enhance the durability of components. By creating a robust protective layer, this process ensures that materials can withstand extreme conditions, including high temperatures, abrasion, and corrosion. This increased durability leads to reduced maintenance costs and increased operational efficiency.

2. Improved Wear Resistance

Tungsten Carbide is renowned for its exceptional wear resistance properties. By laser cladding Tungsten Carbide onto surfaces, the hardness and wear resistance of the coated material are significantly improved. This is particularly advantageous in industries where components are subjected to intense wear, such as mining, oil and gas, and manufacturing.

3. Enhanced Performance

Tungsten Carbide Laser Hard Facing not only enhances durability and wear resistance but also improves the overall performance of coated components. This advanced technology allows for precise control over coating parameters, ensuring uniform deposition and minimal distortion. The result is enhanced performance, increased productivity, and extended service life.

4. Versatility

Another remarkable aspect of Tungsten Carbide Laser Hard Facing is its versatility. This process can be applied to a wide variety of materials, including steels, cast irons, stainless steels, and nickel-based alloys. It is suitable for both new component production and the restoration of worn-out parts, offering a cost-effective solution for businesses in various industries.

Applications of Tungsten Carbide Laser Hard Facing

1. Mining and Construction

In mining and construction industries, where equipment is subjected to extreme wear and abrasive environments, Tungsten Carbide Laser Hard Facing proves indispensable. It can be used to protect components such as augers, buckets, blades, and crushers, extending their lifespan and reducing downtime.

2. Oil and Gas

The oil and gas sector often faces challenges due to corrosive environments, erosion, and wear. Tungsten Carbide Laser Hard Facing provides a reliable and cost-effective solution for protecting components such as drilling tools, valves, pumps, and pipelines, ensuring optimal performance and longevity.

3. Manufacturing and Industrial

Tungsten Carbide Laser Hard Facing has numerous applications in the manufacturing and industrial sectors. From protecting molds, dies, and cutting tools to improving the wear resistance of machine components, this technology offers businesses a competitive edge by enhancing efficiency and reducing maintenance costs.

4. Power Generation

In the power generation industry, Tungsten Carbide Laser Hard Facing plays a crucial role in protecting critical components like turbine blades, shafts, and valves from erosion, corrosion, and wear. The increased durability and performance achieved through laser cladding contribute to improved efficiency and reduced downtime.

Conclusion

Tungsten Carbide Laser Hard Facing is a game-changing technology that empowers businesses in the Business and Consumer Services category to enhance the durability and performance of their components. Powder Keg is your trusted partner in providing high-end laser coating services to help you achieve optimal results. Contact us today to explore the possibilities of Tungsten Carbide Laser Hard Facing for your business.